11/2/2022

| Dr. Patrick Wolf

You want to monitor ammonium (NH4 ) at a wastewater treatment plant or in a waterbody? And you wonder which measuring method is the better one? Then this article is the right one. Here you will learn the differences between an ion-selective sensor and a wet-chemical automatic analyzer and where they are used.

The right technology for your challenges in aeration tanks and at the outlet

Together with nitrate, ammonium is the two most important nitrogen parameters in wastewater treatment. Compliance with the limit values of these two parameters - in the citation forms NH4-N and NO3-N - and thus their monitoring are central tasks of a wastewater treatment plant. In addition to monitoring at the outlet of the plant, upstream control of biological treatment stages is the classic area of application. In the nitrification process, ammonium is oxidized via nitrite to nitrate. Here, measurement technology helps to display the process transparently so that it is possible to react quickly to changing concentrations. The same applies to deammonification, where the existing ammonium is only partially converted to nitrite in a first step. Details on the processes can be found here.

Together with nitrate, ammonium is the two most important nitrogen parameters in wastewater treatment. Compliance with the limit values of these two parameters - in the citation forms NH4-N and NO3-N - and thus their monitoring are central tasks of a wastewater treatment plant. In addition to monitoring at the outlet of the plant, upstream control of biological treatment stages is the classic area of application. In the nitrification process, ammonium is oxidized via nitrite to nitrate. Here, measurement technology helps to display the process transparently so that it is possible to react quickly to changing concentrations. The same applies to deammonification, where the existing ammonium is only partially converted to nitrite in a first step. Details on the processes can be found here.

Outside of wastewater treatment, monitoring of NH4 also takes place in surface waters (especially rivers). In addition to ammonium, the pH value must also be monitored, since ammonium is converted into ammonia, which is toxic to fish, at pH values of 7 and above. This is one of the reasons why the specified effluent values of wastewater treatment plants must be correspondingly low.

Xylem Analytics Germany develops, manufactures and distributes analytical measurement technology worldwide and has over two decades of experience and expertise in the water and wastewater industry. With our proven IQ Sensor Net technology, we offer sensors and instruments for the analysis of all important parameters.

Two methods exist for the continuous measurement of ammonium - sensors with ISE electrodes and wet-chemical ammonium analyzers. This report describes the differences and areas of application.

Product selection - Our recommendation

Application

|

Product

|

Challenge

|

Wastewater treatment

- Biological treatment

- Deammonification

|

AmmoLyt®PLUS 700 IQ

VARiON® PLUS 700 IQ

|

- Good accuracy and continuous measurement

- Controlling

- like AmmoLyt®PLUS 700 IQ

- additional measurement of NO3

|

| Qutlet |

Alyza IQ NH4

|

- High accurancy event at low concentrations

|

| Surface water |

Alyza IQ NH4

|

|

Automatic analyzer for monitoring of sewage algae outlets and water bodies

Due to its high accuracy even in the lower measuring range, the Alyza IQ NH4 analyzer is particularly suitable for monitoring the outlet of sewage treatment plants or surface waters. Nevertheless, it can also be used in nitrification, provided that very accurate measurement is already required there and at the same time one can cope with a measurement interval of ten minutes or longer. Consumables and chemistry are easily replaceable by the end user. A maintenance contract is therefore not mandatory. On our product details page Alyza IQ NH4 you will find further information.

Due to its high accuracy even in the lower measuring range, the Alyza IQ NH4 analyzer is particularly suitable for monitoring the outlet of sewage treatment plants or surface waters. Nevertheless, it can also be used in nitrification, provided that very accurate measurement is already required there and at the same time one can cope with a measurement interval of ten minutes or longer. Consumables and chemistry are easily replaceable by the end user. A maintenance contract is therefore not mandatory. On our product details page Alyza IQ NH4 you will find further information.

ISE sensor for process control in biological treatment

The ion-selective sensors AmmoLyt®PLUS 700 IQ and VARiON®PLUS 700 IQ, on the other hand, are ideal for controlling biological treatment thanks to their continuous measurement and high speed. With the help of this real-time data, processes such as nitrification or deammonification can be transparently displayed and optimized in an energy-efficient manner. You can find an application example here:

The ion-selective sensors AmmoLyt®PLUS 700 IQ and VARiON®PLUS 700 IQ, on the other hand, are ideal for controlling biological treatment thanks to their continuous measurement and high speed. With the help of this real-time data, processes such as nitrification or deammonification can be transparently displayed and optimized in an energy-efficient manner. You can find an application example here:

The good accuracy is completely sufficient for this application. The sensors are also convincing due to the long lifetime of the electrodes (12-18 months), which can also be replaced individually. The use in the outlet is possible depending on the required accuracy. On our product detail pages you will find further information for the sensors AmmoLyt® PLUS700 IQ and VARiON® PLUS700 IQ.

The products in comparison

|

Wet-chemical analyzer

|

Sensor with ion-selective electrodes

|

Measuring principle

|

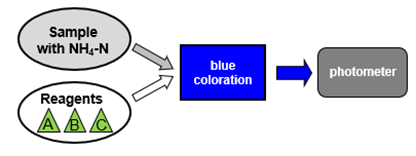

The measurement is performed according to the indophenol method according to DIN 38 406. As the name implies, the indophenol method results in a blue coloration of the sample. The coloration is produced by the ammonium ions originating from the sample reacting under alkaline conditions (pH approx. 12.6) with hypo-chlorite ions and phenol or a phenol derivative.

A suitable catalyst is required to accelerate the reaction. The reaction can be further accelerated by increasing the temperature of the reaction solution. The colored sample is then analyzed photometrically in the red spectral range. The higher the ammonium concentration, the more intense the blue coloration.

|

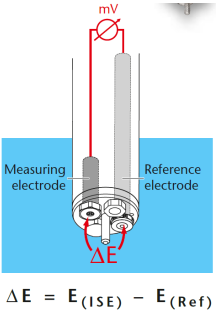

Ion-selective (ISE) online measurement of ammonium and has become well established in the analysis of modern wastewater plants. Xylem has been offering ISE sensors for ammonium for nearly 20 years. Like pH measurement, ISE measurement is based on the selectivity of membranes towards certain substances and is correspondingly easy to handle. Due to this selectivity, a voltage ΔE is formed between the working and reference electrode.

This voltage can be output as a measurement value with the help of a controller. Xylem ISE electrodes are characterized by being stable with respect to their typical applications and over their entire lifetime. Continuous measurement using ISE electrodes, without the need for sample preparation, makes it possible to optimize the treatment plant in terms of cleaning performance and energy consumption. This investment can quickly pay for itself through reduced outlet values. This voltage can be output as a measurement value with the help of a controller. Xylem ISE electrodes are characterized by being stable with respect to their typical applications and over their entire lifetime. Continuous measurement using ISE electrodes, without the need for sample preparation, makes it possible to optimize the treatment plant in terms of cleaning performance and energy consumption. This investment can quickly pay for itself through reduced outlet values.

|

Products

|

|

- AmmoLyt® PLUS 700 IQ

- VARiON® PLUS 700 IQ (incl. NO3)

|

Maintenance

|

- Tubes in contact with sample less than once per year

- Chemical bags depending on parameter and measuring range

- MPV depending on parameter and measuring range; lifetime of six months possible

|

- Matrix adjustment during installation and then as required

- Electrode replacement after 12-18 months

- Cleaning with supernatant and soft toothbrush

- No detergent, no distilled water

|

Calibration

|

Automatic, daily, 2-point |

No calibration, matrix adjustment see maintenance |

Disturbance variables

|

Negligible |

Potassium, compensable |

Measuring interval

|

adjustable

10, 15, 20, 30, 45, 60 min

2, 4, 6, 8, 12 h

|

continuous

|

Both measuring methods are established as standard procedures and provide reliable measurement values. The decisive question in product selection is the area of application or the resulting requirements:

Contact us - We will be happy to help you

If you would like personal technical advice, have a service or repair question or would like to obtain a non-binding quotation, please contact us using the following contact form.