Should you use a saccharimeter or a polarimeter?

The use of the word Saccharimeter is commonplace within the sugar industry but when does a Saccharimeter become a Polarimeter and a Polarimeter a Saccharimeter and are they interchangeable?

The use of the word Saccharimeter is commonplace within the sugar industry but when does a Saccharimeter become a Polarimeter and a Polarimeter a Saccharimeter and are they interchangeable?

This paper investigates the differences between the two and why it’s important to pick the right one based on what part of the industry you are working.

Our Technical Bulletin P001 Polarimetry & Polarimeters

“a simple explanation” describes how a polarimeter works but it mainly relates to the use within general industry. It states:

“In the sugar industry, the rotation is expressed on a different scale, the International Sugar Scale (I.S.S.), denoted as °Z. Polarimeters that are designed for the particular use in the sugar industry are called Saccharimeters,”

But is there more to it than that? Let’s look at the definitions of both polarimeters and saccharimeters.

Polarimeter

An instrument for measuring the amount of polarization of light or (2) an instrument for measuring the rotation of the plane of polarization of light as a result of its passage through a liquid or solution.

Saccharimeter

Any instrument for measuring the strength of sugar solutions, esp. a type of polarimeter for determining the concentration from the extent to which the solution rotates the plane of polarized light.

The above definitions support our own Technical Bulletin P001 in determining that a Saccharimeter (or polarimetric saccharimeter according to OIML, the Organisation Internationale de Métrologie Légale) is a sugar polarimeter with an I.S.S. scale, specifically intended for use in the sugar industry.

So in layman’s terms, a Saccharimeter can be said to be a “sugar polarimeter”.

The International Sugar Scale (°Z)

We’ve seen that a Saccharimeter will display readings of optical rotation in the International Sugar Scale (I.S.S), denoted as °Z. OIML states that “the scale must be linear(*); the range of measurement may be from "-30 °Z to + 120 °Z or only a part of this range; the reference temperature must be 20 °C and saccharimeters must be graduated so that 100 °Z on the scale corresponds to a “normal” sucrose solution.

(*) A linear scale is sufficient in practice although the optical rotation is not strictly proportional to the sugar concentration;

in fact, the deviation from the proportionality does not exceed 0.01 °Z.

A normal sucrose solution is defined by ICUMSA® (International Commission for Uniform Methods of Sugar Analysis) as 26 grams sucrose per 100 cm3.When measured using the wavelength 546.44nm (mercury isotope 198) a normal sucrose solution has an optical rotation of 40.777 °Angular. However, as almost all modern day saccharimeters use a light source based on Sodium, having an average emission of 589.44nm, the corresponding angular rotation of a normal sucrose solution is calculated as 34.626 ± 0.001 °Angular.

What else Differentiates a Saccharimeter from a Polarimeter?

Saccharimeters are used throughout the sugar cane and beet sugar production process. From high accuracy saccharimeters found in the Tare House (the weigh station where sugar cane or beet is collected and analysed for payment purposes), to the sugar mill and sugar refinery as well as in various quality control laboratories throughout the transport network before finally reaching the end user as a pure and unadulterated product.

Funnel Flow Tubes

Saccharimeters are heavily used during the sugar season(s) and they must cope with harsh, humid, and (for cane) tropical environments. Season frequency and duration varies around the globe with the busiest cane production centring around the equator, where a single season can be as long as 365 days a year. Regardless, Saccharimeters need to be reliable, precise and robust.

Saccharimeters are heavily used during the sugar season(s) and they must cope with harsh, humid, and (for cane) tropical environments. Season frequency and duration varies around the globe with the busiest cane production centring around the equator, where a single season can be as long as 365 days a year. Regardless, Saccharimeters need to be reliable, precise and robust.

Saccharimeters also need to provide results quickly as the hot temperatures at Tare Houses can cause sugar to spoil if left waiting. This means the use of a funnel flow polarimeter tube is commonplace that, unlike a standard polarimeter tube that requires cleaning after every reading, allows sample to be applied to the instrument one-after-another without the need for an intermediate flush with water.

Purity & Purity Systems

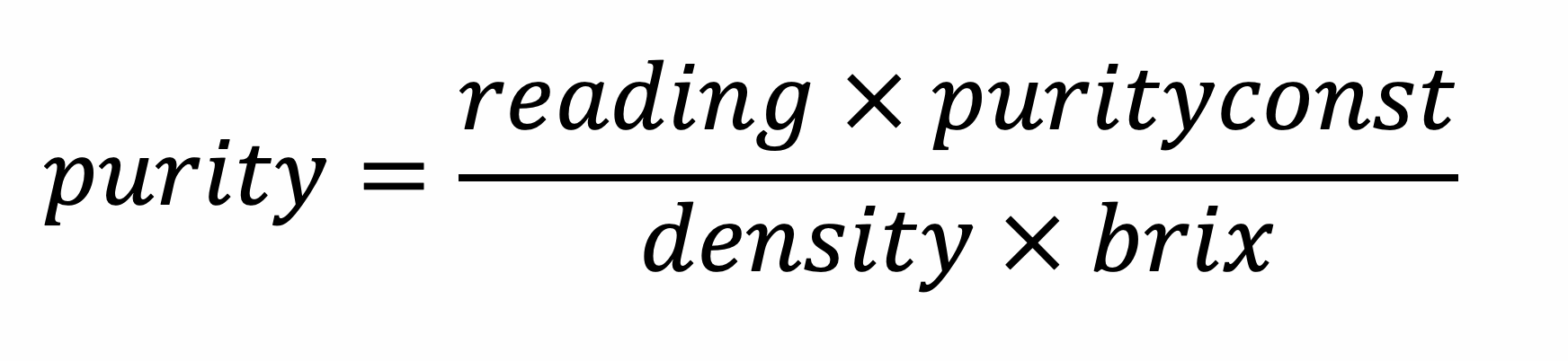

Importantly, the optical rotation (I.S.S) provided by a saccharimeter is just part of the overall analysis of sucrose. In a similar manner to polarimetry (Technical Bulletin P001) where specific rotation is used to factor in tube length and sample concentration, sugar purity is calculated in a similar manner using the following general equation:

where:

is the polarimeter reading in °Z

is the polarimeter reading in °Z

is a user definable purity constant

is a user definable purity constant

is calculated as a function of brix in accordance with the ICUMSA Specification and Standard SPS-4 (1994)

is calculated as a function of brix in accordance with the ICUMSA Specification and Standard SPS-4 (1994)

is the Brix value of the sample

is the Brix value of the sample

In many cases purity and other calculations such as POL may be performed within the saccharimeter to provide a comprehensive assessment of the sugar under test. This is facilitated by manual entry (via keyboard) or direct connection (USB/LAN) of a refractometer that provides the concentration measurement of the sample under test.

In many cases purity and other calculations such as POL may be performed within the saccharimeter to provide a comprehensive assessment of the sugar under test. This is facilitated by manual entry (via keyboard) or direct connection (USB/LAN) of a refractometer that provides the concentration measurement of the sample under test.

More details about the calculations and equations available to ADS saccharimeter users can be found in our blog "Saccharimeters: Sugar Purity".

NIR Saccharimetry

In recent years, as an alternative to the traditional sodium light source used in a Saccharimeter, a near infrared (NIR) light source has been recognised due to its ability to analyse darker samples including raw sugars without the need to clarify using environmentally unfriendly and hazardous lead acetate. NIR saccharimeters are available in single wavelength or dual wavelength versions.

Polarimeters used to measure sugar in general industry

Typically, standard polarimeters used in an industrial environment tend to function as an independent instrument. They are less frequently used than a saccharimeter in sugar production and samples are mostly applied to tubes manually in sequence. As sample throughput is very low, manual cleaning of polarimeter tubes between readings is generally acceptable.

Low volume polarimeter tubes are often used in applications where sample volume is restricted due to its value (e.g. essences) or rarity (e.g. synthetic compounds). They also have the advantage of having UNF threaded connectivity, making them ideal for use in flow systems such as in the analysis of flavours, fragrances and essences.

Industrial polarimeters are often connected to LIMS, especially in the pharmaceutical industry where compliance with FDA regulation 21 CFR Part 11 is paramount.

Polarimeters operate at specific wavelengths in the ultraviolet and visible region with sodium D (589.44 nm) being the most common. Saccharimeters, by comparison, operate in the Vis/NIR spectrum.

In the confectionery industry, where the use of optical rotation or % inversion method is used to control blend ratios of sugar types (for example a 40:60 solution of invert/sucrose) so that a product behaves in accordance with its recipe, a polarimeter is the instrument of choice.

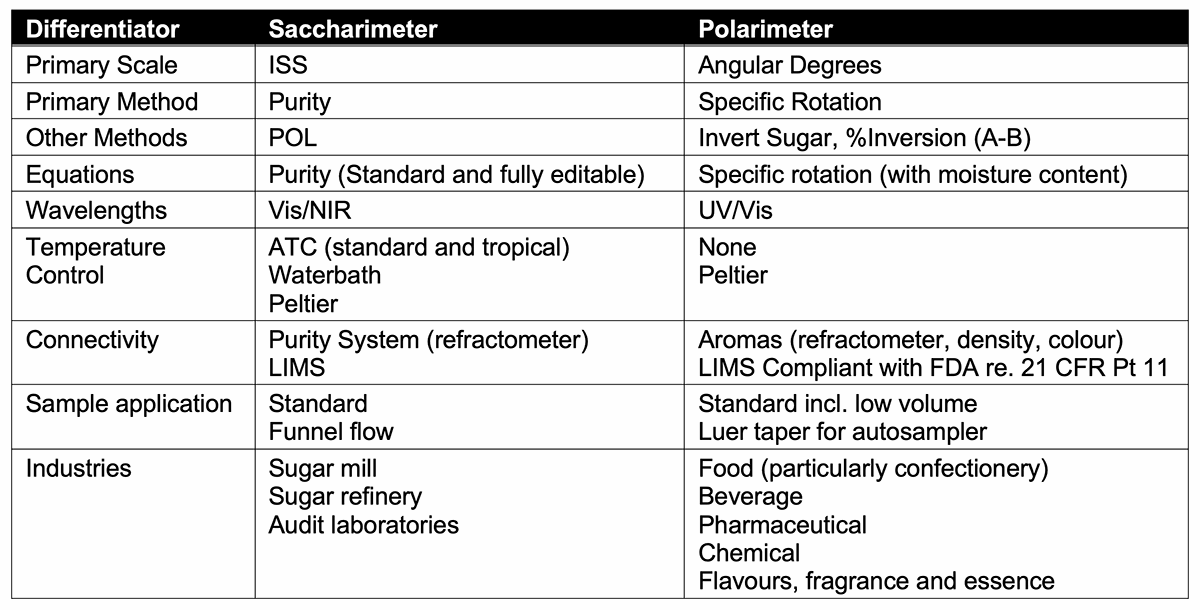

Key Differentiators - Saccharimeter vs. Polarimeter

Conclusion

We now see that if you’re producing sugar from cane or beet, the ADS is the right instrument to choose due to its configuration and ability to be used in harsh, fast moving environments but if you are using sugar to make confectionery, soft drinks etc., then a polarimeter is the better bet as it has additional Methods like Specific Rotation, %invert sugar and % Change (A-B).

Additionally, for producers of sugar, saccharimeters tend to be bundled as packages, offering the best value for money when compared to a self-configured polarimeter that requires add-ons like funnel tubes, special lids and purity software. You’re less likely to miss out a key component when selecting a package and there’s less waste too.

To read more about Bellingham + Stanley's ADS Series Saccharimeters click here. Or talk to us today!

Annex: Useful definitions of regulatory bodies in the sugar industry

OIML:

OIML (Organisation Internationale de Métrologie Légale or International Organization of Legal Metrology) is a worldwide, intergovernmental organization whose primary aim is to harmonize the regulations and metrological controls applied by the national metrological services, or related organizations, of its Member States. www.oiml.org

ICUMSA:

ICUMSA (International Commission for Uniform Methods of Sugar Analysis) is a world-wide body which brings together the activities of the National Committees for Sugar Analysis in more than twenty member countries. www.icumsa.org

ICUMSA is a registered trademark of Verlag Dr. Albert Bartens KG, Berlin, Germany

ISO:

ISO (International Sugar Organization) is the unique intergovernmental body devoted to improving conditions on the world's sugar market through Debate, Analysis, Special Studies, Transparent Statistics, Seminars, Conferences and Workshops. www.isosugar.org