What is Sugar Purity?

Purity (P) is a sugar term used to describe the percentage (by mass) of sucrose in a total Dry Substance (DS) of products throughout production such as juices, syrups etc. Purity is the most common term used by sugar technologists. For example, a product with a purity of 90% means that 100g DS of this product (after all of its water has evaporated) contains 90g of sucrose and 10g of non-sucrose substances. Consumer-quality sugar has a purity of about 100% because it contains almost no non-sugar impurities.

Purity is used to compare the quality of products in various stages of production and, consequently, the efficiency of individual sections of the factory. Higher purity in one product as compared to another is an indication of higher quality (higher sucrose and lower non-sucrose content).

In the case of molasses, the sugar technologists try to produce molasses with the lowest possible purity. This is because the sugar lost in molasses is considered sugar lost (the lower the purity of molasses, the lower the amount of sugar lost to molasses and consequently, the higher the sucrose production).

Purity is measured throughout the process and distribution chain to ensure quality is maintained. Any change in purity may indicate inversion during cane transit prior to milling or perhaps even deliberate adulteration after it leaves the factory in an attempt to falsely heighten profits.

Calculating Purity

Mathematically speaking, purity (P) is the product of the percentage of sugar (S) divided by the percentage of DS, multiplied by 100.

P = S (°Z) / DS x 100

The non-sucrose (NS) content is given as:

NS = DS – S

Specifying Purity

To specify purity, you must indicate the method of sucrose content determination. When the sucrose content is determined by the polarimetric method and DS by the refractometric method (RDS), the result is called Apparent Purity. Roughly translated, this means “approximate purity”.

When the sucrose content is determined by the inversion method (true sucrose) and the dry substance is determined by the refractometric method, the result is called True Purity.

So…

% Apparent purity = Polarimetric sucrose (°Z) / RDS x 100

% True purity = True sucrose / RDS x 100

Let’s look at an example:

Given:

Dry substance (DS) of thick product 62.0% sucrose

Sucrose content (S) of thick product 57.1 (°Z)

Calculate:

Purity of thick product (P)

Non-sucrose (NS) content

P = S (°Z) / RDS x 100

= 57.1 / 62.0 x 100 = 92.1%

NS = DS – S

= 62.0 – 57.1 = 4.9%

Further calculations may also be made in relation to the purity of sucrose, including:

POL

POL = purityconstxZ/density/100

where density is calculated from Brix

Water content

W = 100 – RDS

= 100 – 62.0 = 38.0 %

Purity in Practice

For more than a century, scientists across the globe have experimented and collaborated to define amongst other parameters, purity. ICUMSA® (International Commission for Uniform Methods of Sugar Analysis) by its very name, has established and published uniform methods for determining purity of sugar cane, beet and molasses. Local regulatory bodies, whether they be related to fair payment or environmental matters, also publish methods that sugar factories must follow.

Manufacturers of instrumentation have adopted many of the published formulae making calculation easy. Instruments such as an RFM refractometer may be connected directly to an ADS Saccharimeter to form a purity system, eliminating the need to use tables or make calculations manually. Recently, basic calculations like that shown above have been complimented to include wider considerations that allow scientists to factor in other parameters. Latest ADS Saccharimeters from Bellingham + Stanley has a selection of internationally recognised fully editable formulae offering no end of versatility.

ADS Saccharimeters

The ADS620P and ADS400 Series saccharimeters have the facility to automatically calculate the purity of sugar solutions. The value of purity is derived from the angular rotation of the sample (saccharimeter), the Brix (refractometer) and the density (calculated from Brix). The two ADS types differ by user interface, wavelength, detection method, and achievable accuracy. They both have a Method structure and formulae offering.

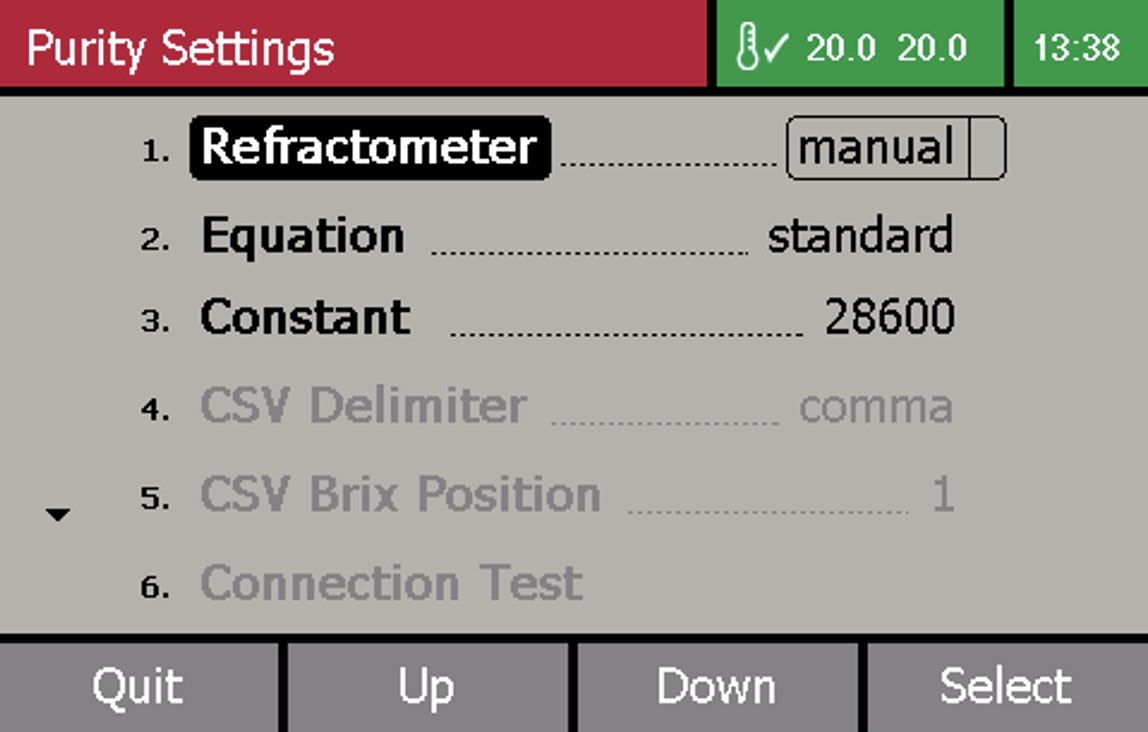

As there are many different methods used throughout the sugar industry for calculating purity, ADS saccharimeters have several adjustable settings which allow the instrument to be setup using the appropriate calculation.

Standard Equation

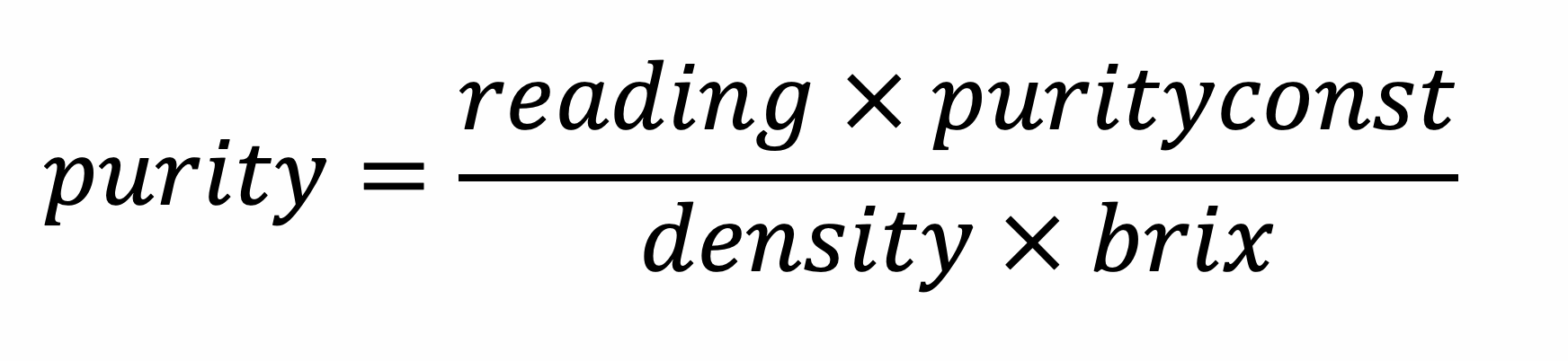

The standard equation used to calculate sugar purity is:

where:

reading is the polarimeter reading in °Z

purityconst is a user definable purity constant

density is calculated as a function of brix in accordance with the ICUMSA Specification

and Standard SPS-4 (1994)

brix is the Brix value of the sample

Selecting & Editing a Purity Equation

Select the desired equation in the Purity Settings Menu to calculate purity.

Standard: The default purity equation (above) will be used.

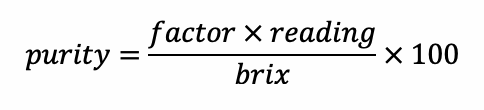

Equation A: Purity will be calculated using the following equation:

where:

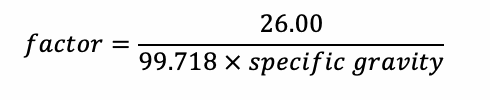

factor is a function of the specific gravity (20°C/20°C) of sucrose:

And the specific gravity is calculated from the Brix value.

reading is the polarimeter reading in °Z

brix is the Brix value of the sample

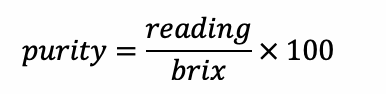

Equation B: Purity will be calculated using the following equation:

where:

reading is the polarimeter reading in °Z

brix is the Brix value of the sample

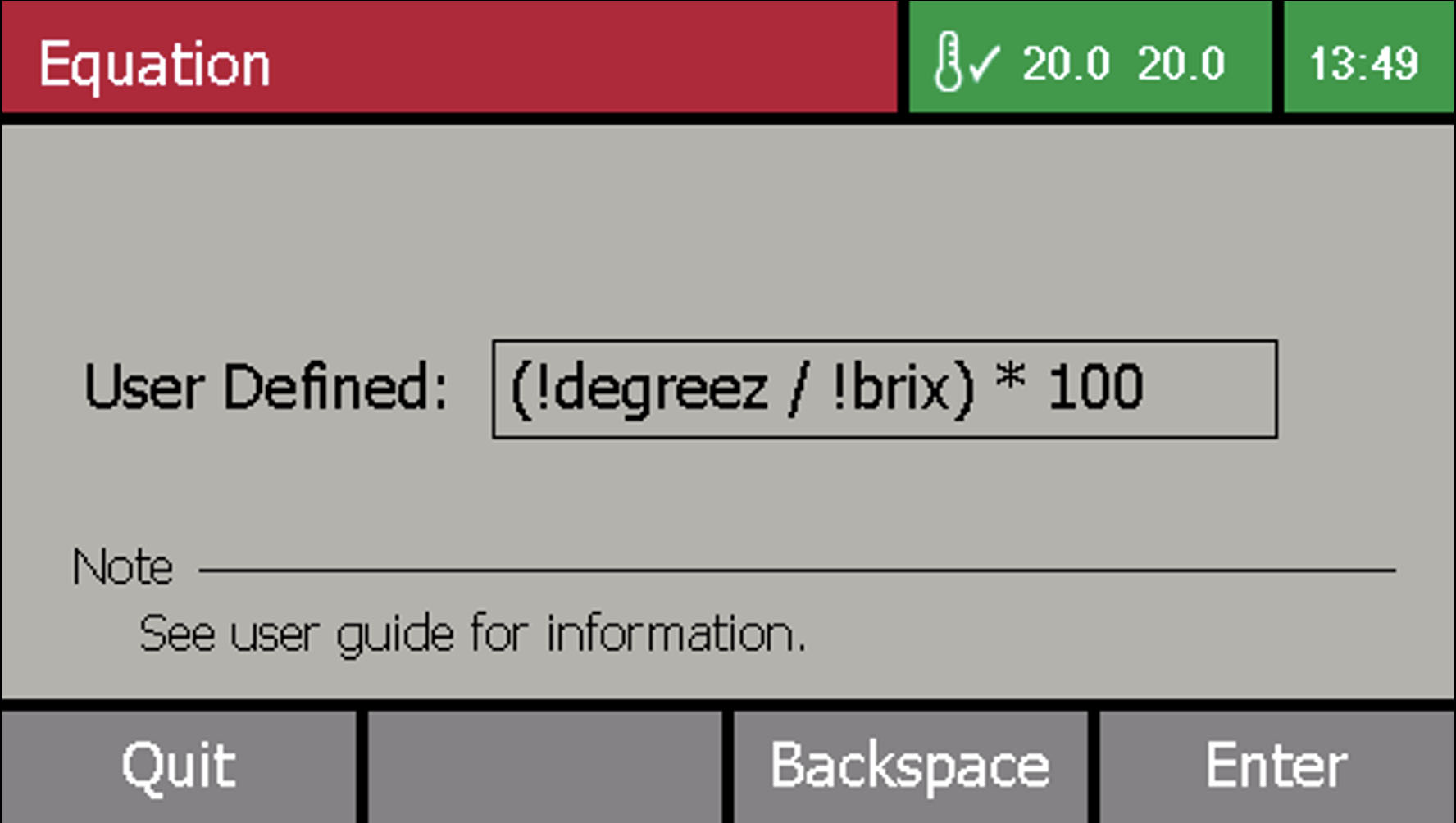

User defined: A user defined equation for purity can be created using the following elements:

!degreez: polarimeter reading in °Z

!degreea: polarimeter reading in °A

!temp: polarimeter temperature in °C

!brix: °Brix by refractometer

!purityconst: Purity scale constant

!density: density derived from Brix value according to ICUMSA SPS-4

NOTE: Standard mathematical operators (e.g. +,-,/,*) can be used. Type any required constants as numbers. When inputting an equation ensure spaces are left between elements.

Equation B as it appears in the purity formulae editor

Purity System Settings

As well as manual keyboard entry, the ADS saccharimeter can receive the °Brix value from a refractometer. The instruments can be interfaced by Network or Serial cable, depending on the generation, make and type of refractometer being connected.

-

- Fixed value (default)

- Manual entry (via keypad)

- Serial (RS232 or USB)

- Direct LAN (instrument to instrument)

- Network

Selecting the Brix input method within the ADS saccharimeter

Manual entry of Brix (no refractometer connection)

When the Purity Method is activated, the Measurement Display will change to accommodate the extra values associated with the purity scale.

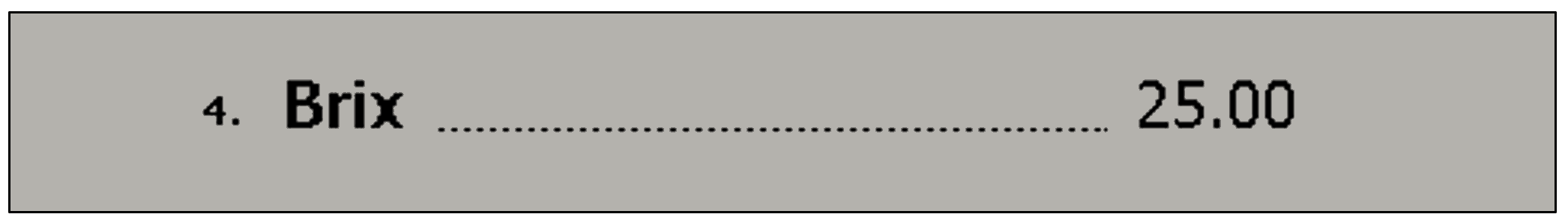

An additional advanced measurement setting within the Method configuration menu then becomes available.

A default Brix value can be set in the Advanced measurement settings. This value is then used each time a measurement is taken on the saccharimeter to eliminate the need to key in a measured brix value. This eliminates a step in the process when always working with a defined concentration of sucrose. For variable Brix samples, users will also be able to enter the actual (measured) value taken from a remote unconnected refractometer at the start of each experiment.

Automatic entry of Brix (refractometer connection) to form a Purity System

The most convenient way of measuring and calculating purity is to connect an RFM or similar make of digital refractometer to the ADS saccharimeter to form a Purity System. Here, the ADS Saccharimeter becomes the primary instrument where the measurement is instigated and the calculations performed with results being displayed on the ADS screen as well as being stored or further communicated from here.

The refractometer is a secondary instrument and is only present to provide the Brix reading automatically when called to do so by the saccharimeter.

The refractometer may be connected directly to the saccharimeter via an RS232/USB cable and adaptor or even via Ethernet where each instrument is connected to the company server and the results routed accordingly.

Picking the right data

When presenting data to an ADS saccharimeter to form a purity system it is important to ensure the right piece element taken from the overall data string is being used in the calculation. For Bellingham + Stanley RFM and most other makes of refractometer .csv format can be used. Here are some tips…

CSV delimiter: If the CSV output of the refractometer does not use a comma to delimit fields, the option to use a semicolon, space or tab delimiter is available.

CSV Brix position: This sets the column of CSV output of the refractometer that contains the °Brix value. For example, the data string from an RFM300-T with all traceability data being output and where the Brix value is 9.33 in column 5:

03/05/18, 14:01:52, qx157, j.smith, 9.33, 20.0, 90, brix, none

The Brix value, 9.33, is in the fifth column, therefore set this value to 5 within the ADS saccharimeter.

Selecting 5 will ensure the Brix value (9.33) is used in the equation

Using these tools, it may be possible to use non-RFM refractometers if a suitable CSV output is available.

Example - Adjusting the Purity Constant:

The purity constant can include any scaling factors or adjustments for a particular purity calculation.

Typically:

purityConstant = zFactor x dilutionFactor x scalingFactor

where:

zFactor = 260 kg/m3 (equivalent to 0.26 g/ml)

dilutionFactor = 1 (if no clarifier is added)

= 1.1 (if 10% extra volume added with clarifier)

scalingFactor = 100 (to display as percentage)

Example 1: The default setting…

purityConstant = 260 x 1.1 x 100 = 28600

Example 2: When measuring a pure sucrose with no added clarifier then the default setting should be set to 1…

purityConstant = 260 x 1.0 x 100 = 26000

Bellingham + Stanley Recommends

Here we have discussed the background to measure the purity of sucrose and applied this to our instrumentation. However, we have not yet discussed the effects of temperature, or the wavelength of light used for the measurement as both play an important part in the overall experiment. Importantly though, the Methods discussed in this blog apply to all ADS Saccharimeters no matter their light source or temperature configuration.

Bellingham + Stanley, a Xylem brand, offers a range of digital polarimeters and saccharimeters, as well as digital refractometers and density meters. The easy-to-use software is familiar across the suite of instrumentation making it easy to take measurements over various parameters.

RFM Digital Refractometers are relied on around the world for precise measurement of Refractive Index and Brix. These robust, simple to operate refractometers pair seamlessly with ADS Saccharimeters to offer a complete sugar purity package. Visit the website for more or talk to us today by visiting our contact page.

Flowcells for refractometers, polarimeters and saccharimeters are also available with funnel flow-through types being the preferred option for use in the sugar industry.

ICUMSA is a registered trademark of Verlag Dr. Albert Bartens KG, Berlin, Germany